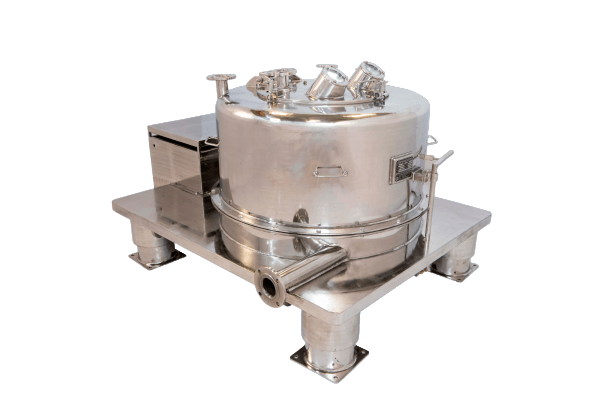

Welcome to Vishwakarma Engineering Industries, the leading Manual Top Discharge Centrifuge Manufacturer in Ankleshwar. Our centrifuges are designed to provide unparalleled performance and efficiency for a wide range of industrial applications in this region.

At Vishwakarma Engineering, we offer premium Manual Top Discharge Centrifuge solutions in Panoli. Our centrifuges are engineered to deliver exceptional separation and discharge capabilities, tailored to meet the specific needs of industries in Panoli.

As a top-quality Manual Top Discharge Centrifuge Manufacturer for Dahej, Vishwakarma Engineering ensures that our products meet the highest standards of durability and performance. Our centrifuges are built to handle demanding processes, making them ideal for industrial applications in Dahej.

Vishwakarma Engineering is a certified Manual Top Discharge Centrifuge Manufacturer, committed to delivering high-quality products that meet rigorous industry standards. Our centrifuges are thoroughly tested to ensure they offer exceptional reliability and performance.

For more information about our Manual Top Discharge Centrifuge solutions or to request a quote, contact Vishwakarma Engineering Industries today. We are your trusted partner for top-notch centrifuge equipment in Ankleshwar, Panoli, and Dahej. Enhance your industrial processes with our high-performance centrifuges.

| CF MODEL | BASKET SIZE DIA X HEIGHT (MM) | VOLUME UNDERLIP IN LITER | BASKET RPM | MOTOR (HP) 1440RPM | FILTER AREA IN SQ. METER | G VALUE | FLOOR SPACE WIDTH X LENGTH X HEIGHT | WEIGHT OF MACHINE APPROX IN KG. |

|---|---|---|---|---|---|---|---|---|

| 36″, MTD / BL | 930 X 450 | 180 | 1000 | 7.5 | 1.24 | 520 | 1350 X 1830 X 1180 | 1100 |

| 48″, MTD / BL | 1235 X 550 | 355 | 850 | 15 | 1.88 | 500 | 1800 X 2225 X 1500 | 2300 |

| CF MODEL | BASKET SIZE DIA X HEIGHT (MM) | VOLUME UNDER LIP IN LITER | BASKET RPM | MOTOR (HP) 1440RPM | FILTER AREA IN SQ. METER | G VALUE | FLOOR SPACE WIDTH X LENGTH X HEIGHT | WEIGHT OF MACHINE APPROX IN KG. |

|---|---|---|---|---|---|---|---|---|

| 12″, MTD | 310 X 200 | 9 | 1440 | 1.5 | 0.19 | 350 | 600 X 830 X 680 | 160 |

| 24″, MTD | 615 X 340 | 55 | 1200 | 3 | 0.63 | 490 | 1030 X 1500 X 900 | 580 |

| 36″, MTD / BL | 930 X 450 | 180 | 1000 | 7.5 | 1.24 | 520 | 1500 X 2000 X 1200 | 1970 |

| 48″, MTD / BL | 1235 X 550 | 355 | 850 | 15 | 1.88 | 500 | 1800 X 2450 X 1500 | 3860 |

| 60″, MTD / BL | 1530 X 640 | 580 | 700 | 25 | 2.59 | 420 | 2100 X 2750 X 1550 | 6900 |

Find Us on Maps

Address